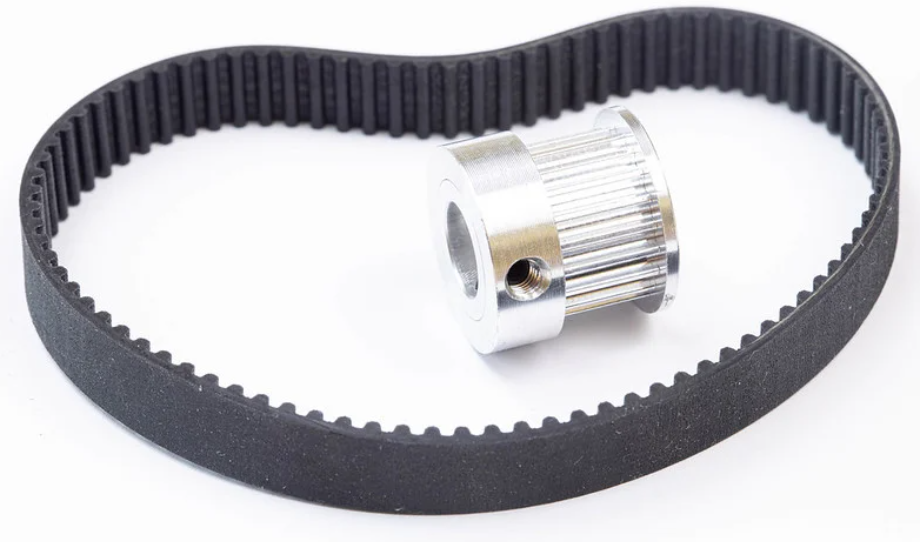

The belt drive system is a common mechanical transmission method widely used in various mechanical equipment and vehicles. Its basic components include belt pulleys and transmission belts. The belt pulleys are usually installed on the motor and the wheels, while the transmission belt connects these pulleys, transmitting power through friction. Specifically, when the motor operates, it drives the motor belt pulley to rotate, and the transmission belt transfers this rotational motion to the wheel belt pulley through friction, thus causing the wheels to turn.

Compared to chain drive, belt drive systems have several unique advantages. Firstly, belt drive systems operate more smoothly with lower noise levels. This is because belt drive relies on friction, while chain drive transmits power through the engagement of chain links and gears, which tends to generate significant noise at high speeds. Secondly, maintenance of belt drive systems is relatively simple, requiring less frequent lubrication and being less prone to rust. This results in lower maintenance costs for belt drive systems in daily use.

Moreover, belt drive systems have higher efficiency and good shock absorption performance, effectively reducing the impact of vibrations on electric bicycles and enhancing riding comfort. This characteristic of belt drive systems has made them increasingly favored in the field of electric bicycles. Compared to chain drive, belt drive minimizes power loss during the transmission process, thus better maintaining the power output of electric bicycles.

In summary, with its advantages of smooth operation, low noise, easy maintenance, and high efficiency, belt drive has become an important choice for transmission systems in electric bicycles. By understanding the basic concepts and operation principles of belt drive, readers can better understand its application value in electric bicycles.

Analysis of the Advantages and Lifespan of Belt Drive Systems in Electric Bicycles

The electric bicycle market is rapidly evolving, and choosing the right transmission system is crucial for the riding experience. Belt drive systems have gradually become the preferred choice for electric bicycle enthusiasts due to their numerous advantages. Firstly, the low noise characteristic of belt drive systems is particularly prominent. Compared to traditional chain drive, belt drive operates almost silently, providing riders with a quieter and more comfortable riding environment.

In addition to low noise, belt drive systems are also known for their low maintenance requirements. Traditional chain drive systems require regular lubrication and adjustment, while belt drive does not need grease lubrication, significantly reducing maintenance costs and time investment. Since belt materials are typically made of high-strength synthetic rubber or polyurethane, their surfaces are not prone to dust and dirt accumulation, nor are they susceptible to rust, further enhancing their cleanliness.

In terms of durability and lifespan, belt drive systems also perform exceptionally well. Studies have shown that high-quality belt drive systems can have a lifespan of over 20,000 kilometers under normal operating conditions, whereas chain drive systems typically need replacement after 5,000 to 10,000 kilometers. The longer lifespan not only reduces the frequency of replacements but also lowers long-term operating costs.

Furthermore, belt drive systems demonstrate reliable performance in various climate conditions. Whether in extreme heat or cold, the stability and anti-aging properties of belt materials enable them to function normally in diverse environments. Especially in humid and rainy climates, the anti-rust properties of belt drive systems are advantageous, ensuring the continuous and efficient operation of electric bicycles.

In conclusion, electric bicycle belt drive systems, with their low noise, low maintenance, high durability, and outstanding performance in various climate conditions, have become the ideal choice for an increasing number of riders.